CMMS Helps Automotive Manufacturing

Toyota recently announced that it achieved a record year of production in 2016 with more than two million vehicles built. Production volume was up 4.4% over the total from 2015. Key drivers of the increased production included low fuel prices, continued stability in the overall economy and strong customer demand for trucks and sport-utility vehicles.

In order to sustain this exciting level of growth, automotive manufacturers must operate lean. Lean, efficient manufacturing depends on machinery working at its peak efficiency. Properly planning preventive maintenance can help meet and exceed production demands. Maintenance programs, coupled with a CMMS can also help support Overall Equipment Effectiveness (OEE) and compliance.

Meet Production Demands

Organizations can better manage influxes of work orders and requests from any browser-based device with work order scheduling software. Managers can also assign work orders to the appropriate technician quickly, and sign off on the work order with a digital signature. As operations increase within a plant or worldwide, stay on top of work progress with list-views of open work orders by type, technician, or department.

Spartan ERV (Emergency Response Vehicles) is a leading manufacturer of custom fire trucks and other rescue vehicles. After implementing eMaint’s CMMS solution, the company saw work turnaround increase 33%, the ability to maintain 75,000 square foot facility and equipment with a single technician, and an in-time completion rate for PMs rose to 85% and steadily improving.

Support For OEE

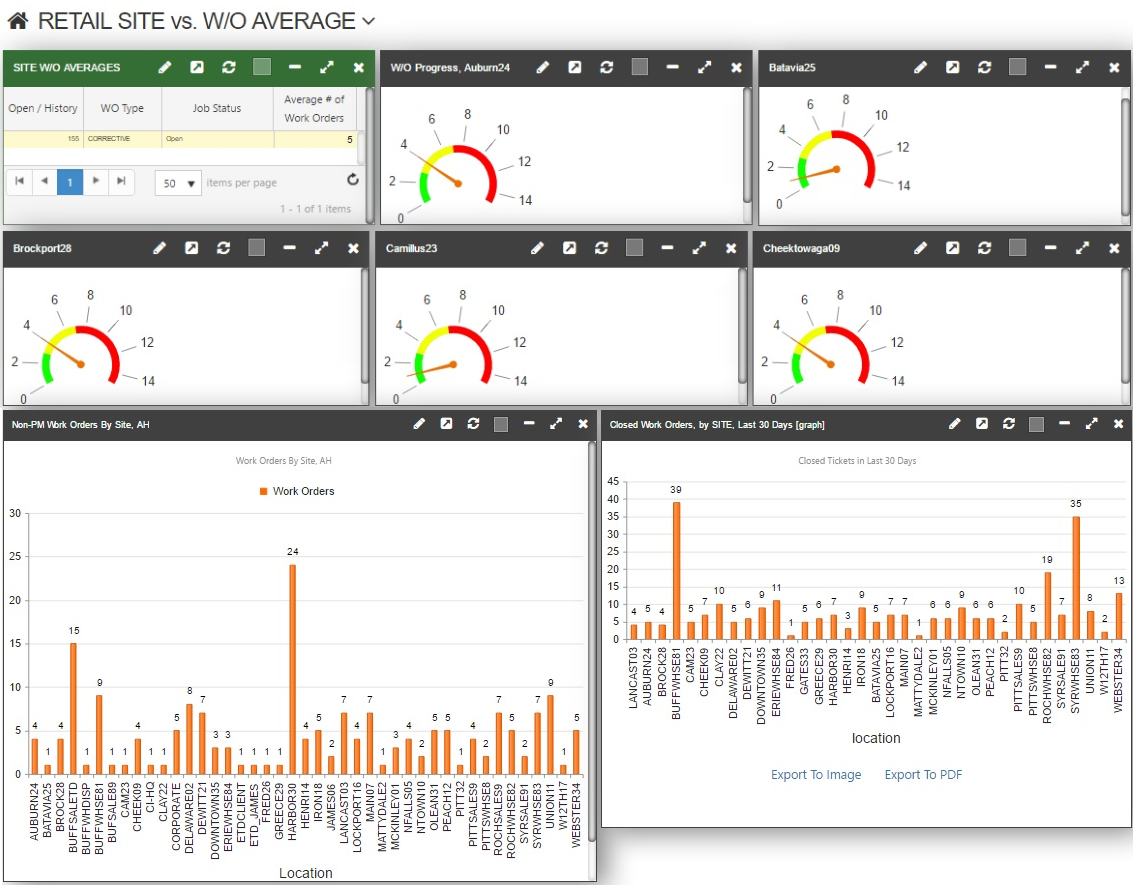

A CMMS can report on key metrics for automotive manufacturers, and OEE is critical for most, if not all organizations. You are enabled to track factors that impact OEE, such as downtime. The reporting and dashboard tools within a CMMS help turn data into insights to share with the production and maintenance crews, as well as management.

From there, you are empowered to make decisions by analyzing historical costs and trends, and take corrective action. CMMS solutions help to support and reinforce a philosophy of continuous improvement for your organization.

For example, eMaint client Dunn Tire has the ability to track and analyze productivity, work orders per location, response time, and maintenance labor and parts costs. The company can benchmark performance across all locations and examine the results.

Achieve Compliance

It is of the utmost importance for automotive manufacturers to comply with regulatory standards such TS 16949, GMP, FTC, EPA and others. By using a CMMS to accomplish tasks such as tracking work order history and inventory, documenting procedures, auto-generate PM tasks and more, compliance becomes less of a headache.

“Everything is very visible. That’s one of the great things about eMaint CMMS. Utilizing the reporting function has helped us better manage maintenance at our four locations, and has made the auditing and certification process much less painful,” said Bill G., Facilities Manager at Troy Design & Manufacturing.