Ready to simplify your facility management? Let eMaint CAFM show you how.

Fill out the form to schedule a free CAFM software demo with a CAFM expert. The demo allows businesses to explain their specific challenges and learn how eMaint simplifies reliability for facilities of all sizes.

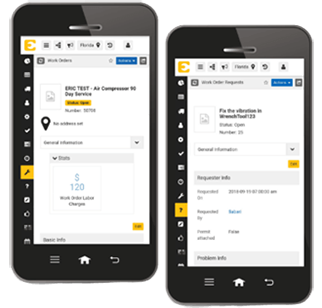

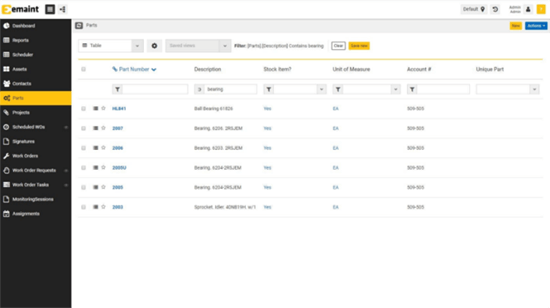

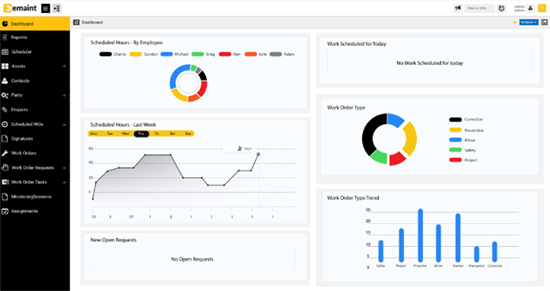

eMaint is an award-winning CMMS, EAM, and IIoT software from Fluke Reliability

Customize your API to help your team save money and resources

eMaint CMMS API unites your individual business processes.

Customer Solutions for every industry

Rated a Top 20 Solution for CAFM Software*

See what our customers have to say about eMaint CAFM Software

*Capterra Top 20: The content for the Top 20 report is derived from independent research and user testing; end-user reviews and ratings; and vendor-supplied and publicly available product and company information applied against a documented methodology. The results do not constitute an endorsement by Gartner or any of its affiliates.

*Software Advice FrontRunners: The FrontRunners badge is a trademark and service mark of Gartner, Inc. and/or its affiliates and is used herein with permission. All rights reserved. FrontRunners constitute the subjective opinions of individual end user reviews, ratings, and data applied against a documented methodology; they neither represent the views of, nor constitute an endorsement by, Software Advice or its affiliates.

*GetApp Category Leaders: The Category Leaders badge is a trademark and service mark of Gartner, Inc. and/or its affiliates and is used herein with permission. All rights reserved. GetApp Category Leaders constitute the subjective opinions of individual end-user reviews, ratings, and data applied against a documented methodology; they neither represent the views of, nor constitute an endorsement by, GetApp or its affiliates.