Simplify Audits With a CMMS

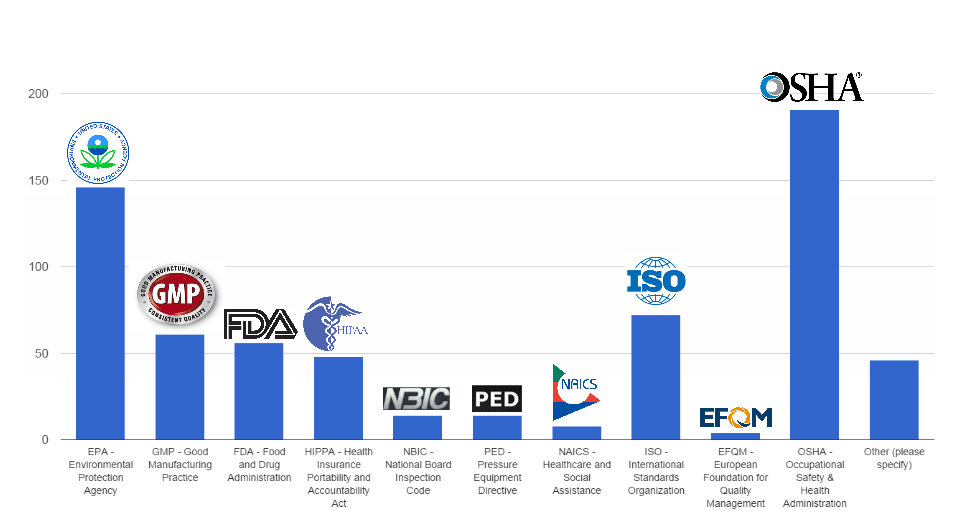

Without the proper system in place, it can become a headache to keep up with the ever-changing standards of audits, and demonstrate compliance at a moment’s notice. In a recent poll, eMaint clients weighed in on which agencies they receive audits from. This information, as well as feedback we hear from customers and others in the maintenance field illustrated that regulatory concerns are at top of mind for maintenance professionals across a variety of industries.

As a result, more and more organizations are using their CMMS systems to help pass audit scrutiny in an organized, streamlined way. For example, one of eMaint’s clients, recently passed a TS16949 audit with eMaint CMMS. TS16949 is an ISO technical specification aimed at the development of a quality management system that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain. Robert McKenna, Technical Advisor at Dana Corporation had this to say:

“The auditor’s listed our maintenance program and our eMaint CMMS software as ‘Best Practice’ in the industry! They were so impressed they asked many questions about how we got started with the CMMS program. Both auditors were happy that eMaint CMMS is being utilized throughout other Dana facilities. They were also very impressed with our hyperlinks and data tracking that was implemented within this program. After the audit, one of their comments was this, ‘We are excited to see this program, it meets all of the new requirements of the ISO 9001 that will be coming in the near future.'”

Your organization can achieve these results by levering an effective maintenance management solution. Features such as Reports and Dashboards, archiving and Preventive Maintenance (PM) tools can help organizations meet compliance standards for quality, environmental, energy, food safety. Organizations are empowered to:

- Access documentation on equipment scheduling and procedures with a few clicks of a mouse

- Electronically catalog spare parts, record part history, and maintain storeroom values

- Provide workers with easy access to safety manuals and procedures

- Track and measure accountability for all maintenance activities performed by each technician

- Generate reports on the information required for inspections and audits

- Ensure on-time completion of critical work orders

- Keep technicians up-to-date with inspection and audit PM tasks

Learn more about how by checking out our white paper “Leveraging Your CMMS to Achieve Compliance.”