What is Maintenance Software?

Maintenance software is a type of software that centralizes all of your maintenance information and provides tools to optimize asset upkeep. The goal of any maintenance management software is to increase the availability, utilization, and reliability of your equipment.

There are many types of maintenance software. A computerized maintenance management system (CMMS) is a maintenance software that enables you to effectively manage, automate, and streamline your operations. Maintenance software is generally cloud-based, meaning that maintenance information is quickly accessible from any device, providing rapid visibility into all your maintenance operations across work sites.

Quality maintenance requires a lot of planning and organization. Every process has to be documented to ensure reliability and sustainability across all business operations. Maintenance software gives users the power to dive into their assets, supplies, floor plans, and utilities to track, monitor, and analyze them.

What is Maintenance Software Used For?

Maintenance software has a plethora of different uses, but here are some of the most helpful:

Minimize Downtime

Automation within modern software has opened the door to optimizing maintenance coordination on many levels, reducing breakdowns and failures in the long run. To minimize downtime, you can implement a maintenance software strategy that extends each asset’s lifespan and eliminates unnecessary waste.

Reduce Costs

Maintenance software is exceptional for saving labor and material costs by showing what parts are in stock and automating work order delegation to the most qualified staff.

Boost Preventative Maintenance

With all asset information easily available, teams can constantly monitor equipment condition. Maintenance software can automatically alert you to any potential issues and schedule preventative maintenance according to standardized practices.

Ensure Safety and Compliance

It’s much easier to comply with regulations and standard operating procedures (SOPs) when guidelines are built into your maintenance software. A robust system can help you check all the boxes to ensure top-tier workplace safety.

Organize Processes

To manage equipment effectively, you need to know what’s available for production on any given day. With all your information in one place, you can easily keep every aspect of your business organized, allowing for leaner operations and constant improvement.

What are the Types of Maintenance Software?

There are many types of maintenance software that have different benefits for teams. Some of the most popular ones are:

1. Computerized Maintenance Management System (CMMS)

A CMMS is a comprehensive maintenance management software system. It collects information on every step in the maintenance process, from inventory management to scheduling and documentation. Through automation and data-driven insights, a CMMS improves the efficiency of all maintenance operations.

2. Asset Performance Management (APM)

APM software plays an important role in valuation and risk assessments by collecting real-time data on all asset performance. It is primarily concerned with reaching reliability goals thus achieving higher revenue and increasing customer trust. Using AI techniques, APM reinforces the asset ecosystem by coupling smart devices with modern tools like augmented reality (AR) to improve engineering and IT systems.

3. Enterprise Asset Management (EAM)

EAM software scans active asset condition and performance during their construction, maintenance, and replacement phases. Its wide range of capabilities lets you compile valuable insights on multi-site infrastructure to keep track of energy consumption, ongoing repairs, and warranties in effect. EAM software puts you in charge of third-party contracts, expanding asset functions and investing in new capital.

4. Enterprise Resource Planning (ERP)

ERP software is responsible for managing and tracking core business operations that transfer data between manufacturing, financial, and supply chain. Done on a single platform, ERP solutions enhance productivity so you can distribute resources based on sound business decisions and the interests of your stakeholders. ERP solutions are also able to drive digital experiences on the retail side.

5. Inventory Management (IM)

IM systems contribute to the quality and delivery of products. They optimize purchase orders by comparing item prices between vendors and promote data connectivity by displaying balance sheets to tell you if there are shortages or cash flow problems in the backlog.

6. Work Order (WO)

Work order software is built for measuring adjustable KPIs and designing templates to collect results faster. To cover the scope of an asset’s life cycle, you’ll also need a CMMS to schedule repeat orders. Since the software captures real-time values, you don’t have to print out records for upcoming inspections — just pull up digital records as needed.

What are the Features of Maintenance Management Software

Maintenance management software solutions offer a wide variety of features and capabilities, including:

- Preventative maintenance management and automation

- Centralized asset management throughout the entire asset lifecycle

- Work order management and automation

- Inventory management, tracking, and automated parts reordering

- Condition monitoring and analysis for predictive and prescriptive maintenance

- Reporting and analytics dashboards

- Digital record-keeping for audit preparedness

- Safety and compliance management

Maintenance management software with an intuitive user interface makes it seamless for users of any level to access the information and tools they need to do their jobs more efficiently.

Who Uses Maintenance Management Software?

Frequent users of the software are employees who have these occupations:

- Maintenance supervisors: Revise and approves SOPs or audit reports to conform to best maintenance practices. Oversee PM programs and the mobility of assets.

- Machine operators: Inspect worn-out machines for signs of damage, then submit work requests to technicians. They may rely on image detection to install parts that require higher precision.

- Reliability engineers: Take readings on maintenance metrics and use them to prepare diagrams or charts. This information is used to weigh the cost limitations against the availability of particular processes and coordinate audits.

- Technicians: Create and declare the failure codes of an asset and finish work orders. They can also use maintenance management software to retrieve the parts to fix an asset whenever the conditions deteriorate.

- Executive leaders: Discuss business forecasts by presenting reports that measure production costs vs. quarterly profits. They are in charge of allocating budgets for marketing and development directives.

- Inventory managers: Fill in the transactions of the inventory database and set the specific quantities of spare parts. This is to ensure there are no shortages, but also that items are not overflowing warehouses.

What are the Benefits of Maintenance Management Software?

There are many advantages to leveraging maintenance management software within your maintenance operations:

1. Centralizes Information

Clear and effective communication throughout your organization is critical. A CMMS provides a single source of truth for all of your maintenance activities. This reduces the risk of miscommunication, ensuring decisions are made based on up-to-date and accurate information while keeping maintenance teams on the same page with their maintenance program.

2. Increases Asset Uptime While Reducing Costs

By helping maintenance teams fine-tune their operations, maintenance management software can increase the effectiveness of your maintenance program. For example, a CMMS aggregates critical condition monitoring data and issues alerts when it detects a potential problem. This enables maintenance teams to respond promptly when and where they are needed. Ultimately, by allowing for more proactive maintenance approaches, maintenance management software reduces costly unplanned downtime and overall maintenance costs.

3. Automates Maintenance Scheduling

The best way to guarantee consistent, proactive maintenance is to schedule regular service ahead of time. Instead of manually scheduling out months in advance, a CMMS can automate the unique maintenance schedule for each machine, saving you time and making sure maintenance is being done preventively instead of reactively.

4. Streamlines Work Order Management for More Efficient Workflows

Management and automation of work orders are the key capabilities of any asset management software. This reduces the risk of errors due to manual work order management while increasing efficiency by making it easy for technicians to see what needs to be done.

5. Simplifies Inventory Management

Schedules and work orders can be as efficient as possible, but if parts aren’t available to service equipment, then everything grinds to a halt. A CMMS can help track inventory levels, individual parts, and orders. It can even be automated to order more as soon as the stock drops below a preset level so that parts are always available wherever and wherever they’re needed.

6. Digitizes and Automates Record-Keeping for Compliance and Audits

A CMMS solution can replace manual paper filing and spreadsheets, making it easier to stay organized and properly maintain all of the necessary documentation in the event of an audit. For example, maintenance management software can be used to automatically log information about every asset in your facility in a centralized location. In case of an audit, this digital record can easily be exported into a file or report. This ensures regulatory compliance and also facilitates faster audits to minimize downtime for investigations.

What Are the Challenges of Implementing Maintenance Software?

What Are the Challenges of Implementing Maintenance Software?

Maintenance management software provides plenty of great benefits, but that doesn’t mean there aren’t potential growing pains with implementing these programs. Successful implementation requires:

Strong Organizational Processes

Maintenance software is not a magical solution that solves all of your problems. If the underlying processes and policies in place in an organization are not strong and consistent, new technology is not going to solve that. Make sure that roles are clearly defined and maintenance processes outlined before implementing new software. Otherwise, any potential efficiency it could provide will be lost in organizational slowdowns.

Training and Buy-In

It takes time to learn how to use any new software. In the beginning, that learning curve may dissuade technicians from using it, especially if it takes longer than previous methods. It’s important to get buy-in from everyone on the team to make the implementation process as smooth as possible. Investing in proper training is crucial to ensure that the shift to new software is seamless and provides the intended benefits.

Cost

Implementing new maintenance software comes at a cost. Not just a high initial cost for the software itself, but the time it takes to train employees and implement it within existing processes. The upfront cost should be offset by the eventual benefits provided, however, it takes time and patience to reach that point.

Data Security

Centralized, real-time insights are great for decision-making and efficiency. But that data can also be at risk if it’s not properly secured. Investing in data security is an extremely important step to protect your business and its most important assets.

How to Choose a Maintenance Management Software

How to Choose a Maintenance Management Software

Key factors to consider when choosing maintenance software include:

Core Capabilities

Ensure the software offers essential features like preventive maintenance scheduling, work order management, and asset and inventory tracking.

Scalability

Choose a solution that can grow with your organization and integrate with other systems, such as SAP and ERP software.

User-Friendly Interface

Look for a simple and intuitive interface that ensures users can quickly and easily access the information and tools they need.

Vendor Support

It’s important to consider more than just features and capabilities when choosing maintenance software. Does the vendor offer the level of support you need to execute the solution effectively within your organization? This matters for successful implementation and continued benefits for years to come.

For example, in addition to its core capabilities, the technology should be expandable to include other tools and maintenance functions, such as vibration sensors or online condition monitoring. Providers should also deliver robust training and support services before, during, and after software deployment to help reduce the adoption curve and enable continuous improvement of the installed system.

Legacy Integrations

It is also important to ensure that legacy systems can be easily integrated into newer software. This will protect the integrity of the databases, save time, and help your team avoid the frustration of working with incompatible systems.

How Do You Use Maintenance Management Software?

To effectively use maintenance management software, follow these general steps:

1. Define Your Objectives

Identify the specific goals and objectives you want to achieve with the software. What KPIs will you track to determine success?

2. Schedule Preventive Maintenance

Use the software’s preventive maintenance and work order scheduling features to create maintenance plans and schedules for your assets. Set up recurring maintenance tasks, assign qualified technicians, and define triggers to ensure the timely completion of your preventive maintenance tasks.

3. Manage Work Orders

Generate work orders for maintenance tasks that come up, planned or unplanned. Assign work orders to technicians, set priorities, and track their progress through the software. Update work orders with completion details and any relevant notes or documentation for future reference and compliance with relevant regulations.

4. Track Asset Maintenance History

Regularly update maintenance records within the software to maintain an accurate history for each asset. Record completed tasks, materials used, and associated costs. This historical data will support future analysis and decision-making.

5. Analyze and Report on Key Learnings

Use the software’s reporting and analytics features to generate customized reports on maintenance activities, asset performance, costs, and other key metrics. Analyze these reports to identify trends, patterns, and areas for improvement.

6. Train and Engage Users

Provide training to your maintenance team and other relevant users to ensure they understand how to effectively use the software. Encourage their active participation and provide ongoing support to address any questions or challenges.

7. Continuously Evaluate and Optimize

Regularly assess the software’s effectiveness in meeting your maintenance objectives. Gather feedback from users and stakeholders, and make adjustments as necessary to optimize your maintenance management processes.

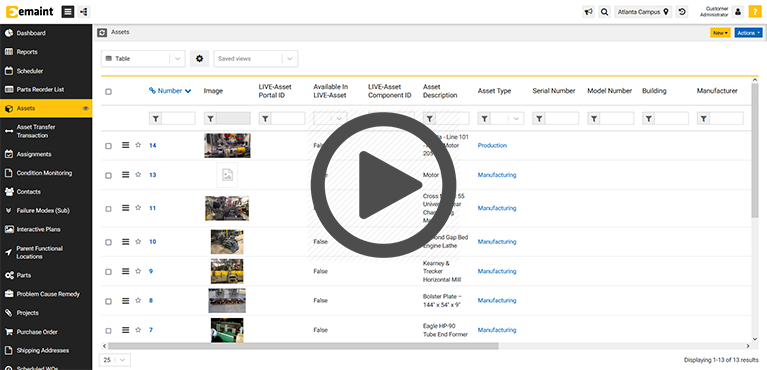

The specific steps and features available will vary depending on the maintenance management software you choose. With eMaintCMMS, you can take a free tour of our software by walking through the featured tabs. We have an asset list view, parts requisitions, project pages, scheduled work orders, and other categories to help you stay organized.

What’s the Difference Between ERP, SAP, and CMMS?

Enterprise resource planning (ERP) systems integrate various departments, including finance, HR, and supply chain, to provide a comprehensive view of business operations. ERP systems are typically used to manage overall business functions and ensure that all departments work together efficiently.

Systems, Applications, and Products in Data Processing (SAP) is a comprehensive ERP system that also integrates core business processes, including maintenance, finance, and supply chain management. SAP offers a broad range of functionalities across various business units, making it suitable for large enterprises looking for a unified system. SAP is a specific brand of ERP software, widely recognized for its extensive capabilities and scalability.

A computerized maintenance management system (CMMS) specifically focuses on maintenance management by optimizing the scheduling, tracking, and execution of maintenance tasks. CMMS solutions are often preferred by organizations that need a specialized tool for managing maintenance activities and improving equipment reliability. Unlike ERP systems, which cover a wide range of business functions, CMMS is dedicated to the operational aspect of maintaining equipment and facilities.

What is Asset Management Software?

Asset management software (AMS) is a type of software designed to help organizations track, manage, and optimize physical assets throughout their entire lifecycle — from procurement to disposal. AMS is a centralized platform for recording and storing asset information, monitoring asset status, facilitating maintenance, and more.

AMS software includes features like asset tracking, asset lifecycle management, status monitoring, maintenance management, asset utilization and performance analytics, and reporting and compliance capabilities.

Why is Asset Management Important?

Asset management is essential to the smooth operation of any facility. It provides asset reliability and performance, keeps production lines running to their maximum potential, saves costs, and ensures safe, compliant business operations.

Effective asset maintenance management can help you:

Optimize Utilization

Effective asset management can ensure that teams use assets to their fullest potential, maximizing productivity and output. When you proactively monitor asset usage and performance, you can more easily identify underperforming or underutilized assets and take data-driven action to improve efficiency.

Increase Reliability

Asset management helps you schedule preventive maintenance tasks, track asset maintenance histories, and manage repairs. This reduces the risk of equipment breakdowns and unplanned downtime, saving time and cost.

Reduce Costs

Proper asset management allows you to track the total cost of ownership for your equipment, including acquisition costs and maintenance expenses. This enables you to identify cost-saving opportunities, optimize maintenance schedules, and make informed asset repair or replacement decisions.

Ensure Safety and Compliance

Asset management ensures compliance by tracking asset maintenance and inspection records, allowing you to demonstrate compliance in the case of an audit. Keeping assets running smoothly can also improve worker safety and prevent emergency maintenance.

Optimize Inventory Management

Effective asset management makes it easier to manage raw materials, components, and spare parts, allowing you to reduce the risk of stockouts, minimize carrying costs, and streamline your supply chain.

Empower Strategic Planning and Decision Making

Managing your assets effectively can give you valuable data and insights to drive your decision-making. By analyzing asset health, performance, utilization, and costs, you can make informed decisions about maintenance planning, asset investments, resource allocation, production scheduling, and more to ensure operational efficiency.

CMMS vs. AMS – How to Tell Them Apart

A CMMS and AMS might seem similar because both can be used to manage your assets. However, there are some important differences.

An AMS is essentially a comprehensive system that focuses on managing assets across the organization throughout their entire lifecycle. Compared to a CMMS, an AMS typically encompasses a broader range of assets beyond maintenance.

In comparison, a CMMS is a subset of AMS that focuses specifically on maintaining and managing physical assets during their usable life. A CMMS is designed to help maintenance teams streamline their operations, schedule and track preventive maintenance, manage work orders, track maintenance history, and optimize performance and reliability.

Maintenance Software Frequently Asked Questions

What Is Maintenance Management Software?

Maintenance management software centralizes all your maintenance data and activities and provides tools to help you optimize asset upkeep. The ultimate goal of any maintenance management software is to increase the availability, utilization, and reliability of your equipment.

What Is A CMMS?

A computerized maintenance management system (CMMS) is a type of maintenance management software that enables you to effectively manage, automate, and streamline your operations. It helps ensure equipment reliability and efficiency by centralizing maintenance tasks, tracking work orders, and maintaining asset histories. Information is accessible in real-time from any device, providing rapid visibility across all work sites.

A CMMS gives users the power to easily track, monitor, and analyze their assets, supplies, floor plans, and utilities. This makes CMMS systems essential maintenance management software for organizations looking to improve their maintenance processes, reduce downtime, and extend the lifespan of their assets.

What Software Is Used for Maintenance?

Modern innovations in automated, cloud-based maintenance software have opened the door to optimizing maintenance coordination on many levels. These advancements help reduce breakdowns and failures in the long run.

Maintenance software programs vary, but some of the key types are:

Preventive Maintenance Software

Automates scheduling and tracking of preventive maintenance tasks.

Maintenance Tracking Software

Monitors and records all maintenance activities, ensuring efficient tracking and reporting.

Maintenance Inventory Software

Manages parts inventory, automating re-orders to prevent shortages.

Asset Management Software

Tracks, manages, and optimizes physical assets throughout their entire lifecycle.

Maintenance Scheduling Software

Helps plan and assign maintenance tasks to ensure timely completion.

Manufacturing Maintenance Software

Tailored for manufacturing industries to help maintain equipment and reduce downtime.

Benefits of Maintenance Management Software

Maintenance management software offers numerous features and benefits that help enhance efficiency and reliability in maintenance operations. These programs are designed to:

Centralize Information

Maintenance management software provides a single source of truth, increasing visibility and reducing miscommunication.

Help With Preventive Maintenance

Automate preventive maintenance schedules to handle issues before they happen.

Streamline Work Order Management

Automate work order processes and increase efficiency.

Manage Inventory

Tracking and ordering parts is easier than ever when the system does it automatically.

Enable Condition Monitoring

Unlock predictive and prescriptive maintenance through data analysis.

Provide Reports and Analytics

Automated dashboards allow for data-driven decision-making.

Automate Record-Keeping

Maintenance management software simplifies audits and compliance, ensuring organized documentation.

Improve Safety and Compliance

Ensure adherence to safety protocols and regulatory requirements.

What Is a Maintenance Program?

A maintenance program is a structured plan that outlines maintenance tasks, schedules, and procedures to ensure the smooth operation of equipment and facilities. It includes preventive maintenance schedules, corrective maintenance, and routine inspections. Effective maintenance programs aim to minimize downtime, reduce repair costs, and extend the lifespan of assets.

What Is Preventive Maintenance Software?

Preventive maintenance software automates the scheduling and tracking of preventive maintenance tasks. Proactively maintaining equipment helps reduce unexpected breakdowns and extend asset lifespan. This type of software allows maintenance teams to effortlessly set up recurring maintenance tasks, assign responsible technicians, and monitor the completion of these tasks to ensure reliability and efficiency.

What Is Maintenance Tracking Software?

Maintenance tracking software records and monitors all maintenance activities. It provides insights into equipment performance, maintenance history, and upcoming tasks, ensuring that all maintenance operations are efficient and well-documented. This software helps organizations track work orders, manage maintenance schedules, and keep detailed records of all maintenance activities.

How Do You Choose the Right Maintenance Management Software?

When selecting maintenance management software, consider features, support, expandability, and integration with legacy systems. Look for robust training and support services to ease user adoption and improve system effectiveness.

eMaint Maintenance Software for Your Team

eMaint maintenance software simplifies scheduling maintenance activities, assigning work orders, and monitoring asset performance through easy-to-understand reports and dashboards. By utilizing the maintenance software’s planning and scheduling tools, your organization will see improved efficiency, reduced maintenance backlog, better control over inventory management, and increased asset reliability and availability.

The Bottom Line

Implementing and using CMMS software offers many efficiency and lifecycle benefits. Overall, it allows teams to align their maintenance practices and activities with other departments and business goals. After all, when you have a system that allows for cross-departmental data sharing, everyone’s job gets a little easier.