What is a Work Order?

A work order is an authorized document issued for maintenance, repair, or operations tasks, specifying the work details, necessary resources, and instructions for completion. It is a critical tool in managing, assigning, and tracking maintenance activities, ensuring tasks are executed efficiently and effectively in alignment with operational goals.

Work orders are a fundamental part of your maintenance operations, and when done well, they help you and your team stay organized, prioritize effectively, and get work done smoothly and efficiently. Work orders are an authorization of maintenance, repair or operations work to be completed. Work orders can be manually generated through a work request submitted by a staff member, client, tenant, or automatically generated through a work order management software or Preventive Maintenance (PM) schedule. Work orders can also be generated via follow ups to Inspections or Audits. eMaint CMMS helps simplify the work order process for maintenance operations.

What Does Work Order Mean?

Work order means, simply put, an order for maintenance work. A work order is a document or digital task that details maintenance work, parts, & process for assets. Work orders are key to organizing a maintenance strategy.

Why are Work Orders Important?

Work orders (WOs) are vital to keeping manufacturing operations running smoothly and maximizing uptime. Done well, work orders make it possible to effectively plan and schedule maintenance to increase the reliability and life expectancy of machinery. A work order should include all of the instructions necessary to complete a maintenance task within a specified timeframe, including all of the parts and labor required.

Using a CMMS work order management software to track your work order history enables maintenance teams to keep accurate records about their assets, track labor and inventory costs, track trends in equipment breakdowns, estimate costs, and, ultimately, enable them to manage their equipment proactively by capturing insights across all their assets. These insights further enable maintenance teams to quickly diagnose problems, identify the source of a problem, and determine what action is needed, when it’s needed, and at what cost.

This documentation also creates a paper trail for performance evaluations and internal or external audits to ensure compliance and accountability in the workplace.

Digitalize Work Orders to Improve Efficiency

Manually created work orders have long been part of the maintenance world. Though paper-based work orders are easy in some ways, they do not perform as well as a long-term or large-scale solution. Paper work orders can also result in communication delays, extra costs (in both time and money) for data entry, and more. In today’s fast-paced maintenance world, paper-based work orders are inefficient — not to mention environmentally unfriendly.

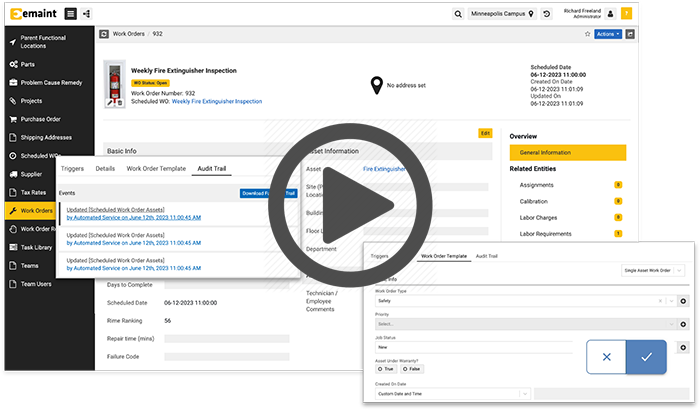

Computerized Maintenance Management Systems such as eMaint CMMS help organizations embrace the power of cloud-based, online work order software and put an end to repeated phone calls, sticky notes, and missing paperwork. Centralizing and streamlining the work order process improves clarity and gets more work done on time.

The Difference Between a Work Order vs. Work Request

There is a subtle but important distinction between work orders and work requests (WR). A work request, also known as a service request, typically refers to a situation where a non-maintenance staffer or customer has submitted a request for maintenance. A work order refers to a maintenance task that has been authorized for the maintenance team to perform.

Work requests serve different functions, but they also look a little bit different. For example, a work request typically briefly describes the issue (landscaping work, leaky pipes, changeovers, etc.) to mark the start of a maintenance flow. A work request is usually classified by the type of industry, business, or priority, for example, calling an emergency if a chemical spill is discovered.

Meanwhile, a work order is only issued after a request has been approved, where the existing budget, criticality, and age of the asset are taken into consideration before work begins. Work orders can fall under a few different categories, including preventive maintenance, inspection, electrical, and safety routes.

What is the Difference Between a Work Order and a PO or Invoice?

A work order, purchase order (PO), and invoice serve different purposes within an organization. A work order is a request for maintenance or service work, detailing the tasks to be performed. In contrast, a purchase order is a document sent to suppliers to procure goods or services, specifying the items, quantities, and agreed prices. An invoice is a bill issued by a supplier to request payment for goods or services provided. While a work order initiates maintenance tasks, a PO initiates purchasing activities, and an invoice facilitates financial transactions and payment processing.

There is a subtle but important distinction between work orders and work requests (WR). A work request, also known as a service request, typically refers to a situation where a non-maintenance staffer or customer has submitted a request for maintenance. A work order refers to a maintenance task that has been authorized for the maintenance team to perform.

Work requests serve different functions, but they also look a little bit different. For example, a work request typically briefly describes the issue (landscaping work, leaky pipes, changeovers, etc.) to mark the start of a maintenance flow. A work request is usually classified by the type of industry, business, or priority, for example, calling an emergency if a chemical spill is discovered.

Meanwhile, a work order is only issued after a request has been approved, where the existing budget, criticality, and age of the asset are taken into consideration before work begins. Work orders can fall under a few different categories, including preventive maintenance, inspection, electrical, and safety routes.

Work Order Procedure: Stages of a Work Order

The work order procedure typically begins with identifying and reporting a maintenance need. The requester fills out a work order form, providing details such as the nature of the problem, location, and urgency. The work order is then reviewed by the maintenance manager, who assigns it to the appropriate personnel and schedules the task. Once assigned, the maintenance team performs the required work, updating the work order status as they progress. Upon completion, the work order is closed, and any relevant details, such as parts used and time spent, are recorded. This systematic approach ensures efficient and effective maintenance management.

There are five steps in the process of creating and approving a work order:

1. Identify the task

The work order process starts when there is a task that needs to be completed. This could be triggered by unforeseen problems like a new service request or an emergency (unplanned maintenance). However, it can also be triggered by predefined activities like preventive maintenance tasks or routine inspections (planned maintenance).

2. Create a new work request

Once the task is identified, a maintenance request is submitted to the maintenance team. If a machine breaks down unexpectedly, for example, a work request will be submitted to the maintenance team to repair it. If there’s a planned maintenance task, a CMMS like eMaint can automatically issue a work order at the appropriate time.

3. Prioritize the work

When requests are submitted, it’s up to the maintenance team to determine the urgency of the request. Some requests will be more time-sensitive then others, depending on their downstream impacts. A CMMS makes it easy to assess the priority of your work orders based on the team’s workload and the impact of the issue on production, and then schedule your maintenance tasks accordingly

4. Complete and document the work

The work order is then assigned to a technician to take action. They will complete the task and document what they did under the asset’s records.

5. Analyze the results

Don’t stop there. Your work order history offers valuable insights into your equipment and your existing processes to drive continuous improvement. Be sure to measure and adjust as needed.

How to Write a Work Order – Writing, Creating, & Filling Out

The standard WO form should have the following fields:

- Name of the requesting department

- Description of the failure type

- The date of fulfillment

- Required parts and tools

- Expected hours of work

- Who is assigned to the task?

And finally, your work order program should adhere to the established guidelines for consistency with relevant compliance standards in the event of an audit.

Writing a work order involves detailing the specific maintenance or service task required. Begin by identifying the requester and providing contact information. Clearly describe the issue or task, including relevant details such as the location and equipment involved. Specify the priority level to help maintenance teams prioritize their workload. Include any necessary attachments, such as photos or diagrams, that can provide additional context. Finally, allocate resources, such as personnel and materials, needed to complete the task. Using a structured format ensures that all essential information is captured, facilitating efficient and effective task execution.

Best Practices for Managing Work Orders

Effective management of work orders involves several best practices. Firstly, ensure work orders are detailed and complete, providing all necessary information for task execution. Use a centralized system, like a CMMS, to track and manage work orders, ensuring visibility and accessibility. Prioritize tasks based on urgency and impact on operations. Regularly review and update work order statuses to keep all stakeholders informed. Foster clear communication between maintenance teams and requesters to address any questions or changes promptly. Finally, analyze work order data to identify trends and areas for improvement in maintenance processes.

Establish your maintenance goals and KPIs. These goals and performance metrics provide a framework for evaluating your work orders. They help define your organization’s maintenance strategy and keep your team on track.

Clearly define roles and responsibilities. Having clear roles in your work order process can help ensure more efficient and accurate task execution. By clarifying who is authorized to create, assign, prioritize, complete, and review work orders, you avoid duplication, unauthorized work, and miscommunication.

Choose the right triggers to automate your work orders. Common triggers include breakdowns, time-based, event-based, usage-based, and condition-based triggers. Use a CMMS to automate work orders based on these triggers. For example, eMaint makes it possible to automatically schedule work orders based on equipment health data, so you can resolve problems early–before they lead to failure.

Continuously analyze and improve your work order process. Remember, effective work order management isn’t a one-time task. It’s a continuous process of refinement and adaptation, which can be facilitated with the use of a good computerized maintenance management system (CMMS). This will help your team adhere to the established SOPs and best practices, enhancing productivity and maintenance outcomes.

Work Order Apps

A work order software app, also known as a mobile CMMS, is the smartphone or tablet version of a work order software, making on-site maintenance more attainable than ever. Work order software apps allow technicians to enter data from mobile devices as they complete work orders. Using a mobile CMMS app can also save time and effort. For example, some work order software apps can auto-fill data, saving time compared to filling everything out manually.

For planning and scheduling preventive maintenance tasks, technicians can use a phone or tablet to track in-progress work orders, as well as assets that still need to be serviced. The app also provides them with information about the historical performance and inspection records at their fingertips, enabling them to adjust settings or make timely repairs.

The Benefits of Digital Work Order Software

Digital work order software, such as a computerized maintenance management system (CMMS), significantly increases workflow efficiency, reduces errors, increases visibility and insight, and ultimately helps keep your maintenance operations running smoothly.

For one, by replacing manual and often paper-heavy processes with automated digital workflows, maintenance teams can streamline and expedite tasks like creating, assigning, and tracking work orders. Furthermore, real-time status updates enable managers and teams to quickly respond to changing circumstances. This enhanced speed and flexibility save valuable time and resources and can help reduce unexpected or extended downtime.

Digital work order systems also help reduce the errors associated with manual data entry. Accurate data is crucial for both informed decision-making and compliance. By centralizing all information in a single, easy-to-access platform, a CMMS software ensures consistent and reliable data.

In addition, digital work order software facilitates better communication among team members. With all data stored centrally and available in real-time, teams have instant access to all the information they need to carry out their work. This promotes transparency and collaboration, allowing for quicker issue resolution and preventing potential bottlenecks. Furthermore, by enabling teams to communicate more effectively, digital work order software ensures that operations continue to run smoothly and efficiently, maximizing productivity and ultimately boosting the organization’s bottom line.

What is a Work Order Used For?

Work orders are used to formalize and track maintenance, repair, and service tasks within an organization. They provide detailed instructions and allocate resources for tasks such as equipment repairs, preventive maintenance, and facility upkeep. Work orders help ensure that maintenance activities are carried out systematically and efficiently, reducing downtime and enhancing operational reliability. They also serve as documentation for completed work, supporting compliance with safety and regulatory standards. By using work orders, organizations can manage workloads, prioritize tasks, and maintain accurate records of maintenance activities.

- Offer an explanation of the problem, repair, or installation

- Schedule resources and tools needed for maintenance

- Provide technicians with detailed instructions on the work to be performed

- Document the labor, materials, and resources used to complete the work

- Track all maintenance and repair work that has been performed on each asset

What Information to Include in a Work Order

A work order should include several key pieces of information to ensure clarity and effectiveness. Essential elements include the requester’s name and contact details, a detailed description of the task or issue, and the location of the problem. Additionally, specify the priority level, which helps in scheduling and prioritizing tasks. Include details about required resources, such as personnel, tools, and materials. Attach any relevant documents or images that can aid in understanding the task. Finally, provide a target completion date to set expectations and help manage workloads.

How to Use a CMMS for Work Order Management

Work orders are the heart of a maintenance program. The tools within a CMMS help organizations stay up to date on labor, projects, and resources. A CMMS can help organizations take control of both their work backlog and upcoming work, boost productivity, and manage compliance. There are a few keys to effective work order management.

Work order management refers to the process of prioritizing, completing, and documenting maintenance work orders in a timely manner. While this might sound simple, the process is time-consuming and prone to error when done by hand. For example, work orders filled out on paper and filed away in cabinets are easy to misplace, and manual spreadsheets are slow to be updated with new information. Instead, leveraging a robust work order management software, such as a computerized maintenance management system (CMMS), accelerates and streamlines this process while ensuring accurate, up-to-date documentation. When implemented effectively, this approach can be affordable and scalable in a facility, enabling maintenance teams to reduce unplanned asset downtime and save costs.

Lifecycle of a Work Order: Work Order Management Process

The work order management process typically starts with a maintenance manager accepting a work order and passing the request along to a technician to fulfill. The work order form communicates maintenance through a lifecycle of six steps.

Task Identification: Identify what needs to be done to resolve a maintenance issue.

Work Order Creation: Complete a work order request form to authorize maintenance tasks.

Work Order Approval: Maintenance management decides if there is a legitimate need.

Priority Assignment: Work orders are assessed by considering the urgency, existing backlog, and team availability.

Distribution and Execution: Approved and prioritized work orders are printed and given to technicians for them to perform the activity.

Result Documentation: Workers document what occurred in an accurate and timely manner.

The work order can be closed once all services were rendered and the job is complete.

What are the Four Main Different Types of Work Orders?

1. Inspection Work Orders

Inspection work orders arrange for a technician to come and inspect a particular asset. If a problem is detected during an inspection work order, the maintenance technician would then create a new work order to resolve the issue.

What triggers an inspection order will depend on your maintenance strategy. For example, if you are using a preventive maintenance strategy, your plant may require workers to inspect all of your equipment at regular, time- or usage-based intervals. If you are using a condition-based predictive maintenance strategy, your CMMS may issue an inspection work order in response to an unexpected change in your machine’s real-time condition, such as a sudden increase in vibration.

2. Preventive Maintenance Work Orders

Preventative maintenance work orders are used to schedule routine servicing for all of your equipment and assets. You can leverage a CMMS software to automatically schedule routine cleaning, lubrication, and other preventive maintenance tasks at a time that’s convenient for your production schedule and for your maintenance team.

3. Emergency Work Orders

Emergency work orders are created in response to an unexpected breakdown. These work orders require an immediate response to avoid costly downtime. When responding to emergency work orders, technicians should record why the asset failed, what was done to restore its normal operating condition, and recommendations for preventing this type of failure from occurring again.

Tracking your emergency work orders in a CMMS system can help you determine where your maintenance strategy has room for improvement: Do the same machines keep breaking down? How quickly is your maintenance crew addressing these problems? How much time is passing between breakdowns? Tracking and analyzing this information over time can help you optimize your maintenance approach, reduce unplanned downtime, and save on maintenance costs.

4. Corrective Maintenance Work Orders

Corrective maintenance work orders are issued to fix new faults before they become serious. Technicians might discover the fault while performing routine inspections on your equipment. Or, if you’re using a predictive maintenance approach, your AI tools might diagnose a new fault in your equipment. A corrective maintenance work order can include repairing or replacing worn or damaged parts on your equipment. In addition, corrective work orders can be scheduled, unlike an emergency work order.

Examples of Maintenance Work Orders

An effective work order should be clear, specific, and detailed. It must also be precisely worded to avoid confusion or misinterpretation and to provide a clear document trail of the asset’s maintenance history.

Work orders should describe the problem at hand and should answer the following questions:

- Which asset needs to be repaired? Where is the asset located?

- Which parts, if any, need to be replaced?

- Which tools will the maintenance crew need to bring with them?

- How many workers are needed to perform this job? What kinds of skills do they need? Will you need to call in outside workers?

- What’s the timeline for performing this job? Is this a preventive maintenance project that must be done on a fixed date? Is this an urgent repair on a key asset that needs to be handled immediately?

- What costs are involved in this job?

- Who is requesting the job? Who authorized the work?

Work orders also fill a record-keeping function. Plant managers can look back over past work orders to track how often assets need repairs, or to assess the success of their maintenance strategy.

What are the Different Work Order Management Approaches?

The two primary approaches to work order management are manual (using pen and paper, spreadsheets, and/or whiteboards) and automated (leveraging a work order management software to automate work order creation and documentation workflows).

Manual work order methods were once the norm and can still be effective for smaller organizations that handle a low volume of work orders. However, a CMMS stands above as the most reliable system that makes it easy to prioritize work orders, automatically distribute them to available technicians, and instantly update maintenance records with the most up-to-date information.

Enterprises should adhere to the best practices of work order management to have more control over their work orders. That means employing a model suitable for managing large volumes of requests instead of just relying on a CMMS to get the job done.

Managing Work Order Requests

Not all work can be planned ahead of time. For corrective work or customer needs, there is a request system. Maintenance managers can tailor workflow processes for request submission, approval, rejection, and completion to the specific needs of their organization. Identifying a workflow process ensures:

- Standard Operating Procedures (SOPs) are adhered to by all users

- Work goes through an approval process

- Areas of responsibility and expectations are clear for users

- Periodic process auditing is performed

- Valid data is being entered into a CMMS

- Efficient communication flow

With eMaint, organizations can choose from three work order request submission options:

- Work requestors are given an eMaint user login that allows them to submit requests and view the history and status of their requests

- Work requestors send an email to a designated email address that gets converted into an eMaint work request

- Work requestors submit requests to eMaint through a customized web form embedded on a company’s website or intranet

The work request tools in a CMMS reduce communication errors. Organizations can send requestors automated email alerts when a work request is approved or rejected, followed by an automated email alert with a satisfaction survey once work has been completed.

With modern mobile CMMS solutions, requestors can submit work order requests whenever and wherever using their mobile device. Requestors can attach pictures to their reqs, including pictures of equipment needing repair.

What is Work Order Software?

CMMS software makes it easy for organizations to increase on-time work completion, improve workflow efficiency, keep track of project due dates, and more.

- Work Order Assignment – Using features such as eMaint’s maintenance scheduling tools, maintenance planners and schedulers can directly assign work orders to staff, contractors, or vendors for specific days, times, and locations. Assigned and unassigned work orders can also be viewed on a calendar display, and work can easily be reassigned when necessary.

- Scheduling Calendar – View a calendar by day, week, or month with all labor resources and open work orders, or adjust calendar views and filter work by employee, work order type (such as Preventive Maintenance schedules), and more. Organizations can also use the PM Projection feature to plan upcoming work and ensure the right parts, labor, and tools are available.

- Reports & Dashboards – Leverage Reports & Dashboards to stay up to date. Categorize work orders by type, technician, department, or any other user-defined field.

- Mobile Maintenance – Using mobile CMMS maintenance services such as eMaint’s MX Mobile, organizations can access real-time data and perform functions throughout their facilities and on the road, including submitting and approving work requests, signing and closing out work orders, and more.

Tracking Projects

Major overhaul and renovation projects can be a headache, but the management process doesn’t need to be. With eMaint’s project management tools, organizations can easily create projects and assign and track work orders from project inception to completion. A CMMS organizes data in one central place. Assets, inventories, and actions that impact operational goals can all be handled from one platform.

With Gantt Charts, users can get a clear visual understanding of work order completion rates compared to a project’s end date.

What is a maintenance work order?

A maintenance work order is a formal directive that authorizes specific maintenance tasks on equipment or facilities. It details the job description, necessary resources, and execution steps, providing a structured approach for maintenance teams. This document is essential for tracking, scheduling, and ensuring the accountability of maintenance operations.

What is a Maintenance Work Order?

A maintenance work order is a formal directive that authorizes specific maintenance tasks on equipment or facilities. It details the job description, necessary resources, and execution steps, providing a structured approach for maintenance teams. This document is essential for tracking, scheduling, and ensuring the accountability of maintenance operations.

What’s the Difference Between a Work Request and a Work Order?

A work request is an informal notification of an issue or a needed task, typically submitted by staff or customers. In contrast, a work order is a formal document issued in response to a work request, authorizing and detailing the specific tasks. It includes assigned resources, timelines, and instructions, moving from identification to actionable steps.

What is the Purpose of a Work Order System?

The purpose of a work order system is to streamline and manage the process of handling maintenance tasks from initiation to completion. It helps track progress, schedule resources, ensure accountability, and maintain historical records of the work done, which improves operational efficiency and asset management.

What is the Difference Between Work and Maintenance Orders?

While a work order can apply to various operational tasks, including maintenance, construction, or IT services, a maintenance order refers explicitly to work orders created for the upkeep, repair, or inspection of equipment and facilities. All maintenance orders are work orders, but not all work orders are maintenance orders.

How to Fill out a Maintenance Work Order?

To fill out a maintenance work order effectively:

1. Description of Issue: Clearly describe the problem or maintenance task.

2. Location: Specify where the work is to be performed.

3. Priority: Assign a priority level to guide timely action.

4. Assigned To Detail who is responsible for completing the task.

5. Estimated Time: Provide an estimate of how long the task should take.

6. Required Tools and Materials: List all necessary tools and materials.

7. Safety Notes: Include any safety precautions or relevant regulations.

What is an Example of a Work Order?

An example of a work order might be a document issued to repair a faulty HVAC system in an office building. It would specify the nature of the problem, the location, the technician assigned, necessary tools, estimated completion time, and any safety precautions.

What are the Functions of a Work Order?

The functions of a work order include:

- Authorization: Legitimizing the commencement of a task.

- Documentation: Providing a record of tasks, resources, and time.

- Coordination: Ensuring resources are scheduled and available.

- Tracking: Monitoring progress and status updates.

- Analysis: Offering data for operational insights and future planning.

What Should be in a Work Order?

A work order should contain:

- Work Description: Detailed explanation of the task.

- Requestor Information: Who requested the work, and what is their contact information?

- Assigned Personnel: Names and roles of individuals responsible for execution.

- Timeline: Start and end dates, including any milestones.

- Resources: List of materials and equipment needed.

- Instructions and Standards: Specific procedures or standards to follow.

- Approval Signatures: Sign-offs are required to start and complete the work.